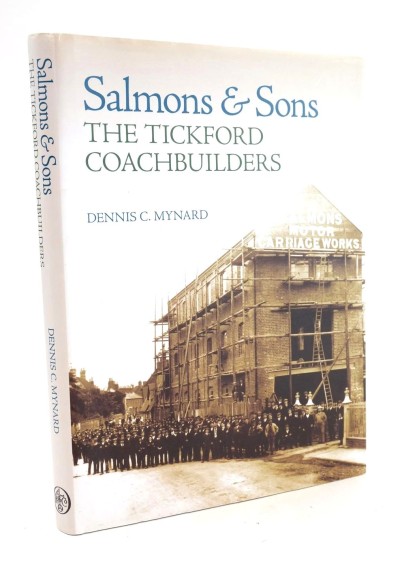

Salmons & Sons - The Tickford Coachbuilders by Dennis C. Mynard

This year I was lucky enough to go to a few classic car shows where I saw, among many other makes and models, a selection of Ford Capris. My husband mentioned that there used to be a Tickford Capri which was a limited-production, high-performance version of the Ford Capri Mk III 2.8i. A couple of weeks later I came across this book in our shop, Stella and Rose’s, called The Tickford Coachbuilders so I thought I must have a read as it seemed too much of a coincidence to ignore.

My husband was correct; it is the same company that did go on to be part of the development of the Ford Capri. The book tells the company history from inception all the way through to virtually the present day, the people who worked there, the types of cars that were produced, the processes in making the cars, newspaper and personal reviews plus individual accounts of what it was like to work there.

At the beginning of the book there is a touching introduction written by the author, Mr Dennis Mynard, whose father worked at the factory. He wrote the book out of fondness for his father, the Salmons family and all the people who worked there.

In the front and back of the book there is a layout of the plans of the factory, buildings and offices which shows just how big it was. This helps as a point of reference throughout the book.

The book begins with Mr Joseph Salmons who was the founder of the company in 1830. He was born in 1796 and had eight children. His two eldest sons, Thomas and Joseph Jnr, were to become coachbuilders at the company.

Joseph Salmons started his working life as a wheelwright and he managed to buy a piece of land on the Tickford Estate where he started his business making carts and wagons. In around 1830 Joseph’s Carriage works was formed and by 1844 the business was well established. Records show that, by 1851, he employed 20 men and labourers and, by 1852, 26 men and 8 boys plus a house servant.

His sons, Thomas and Joseph Jr were made partners in 1867, and they renamed the company Salmons and Sons, but by the time Joseph died in 1878 Thomas had wanted to retire, so the partnership was dissolved, and Joseph Jr took on his eldest son George as partner.

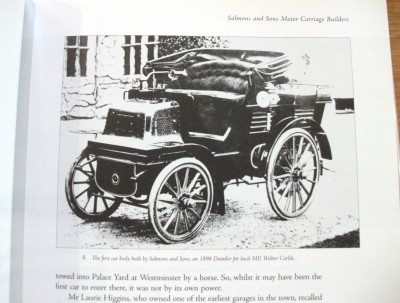

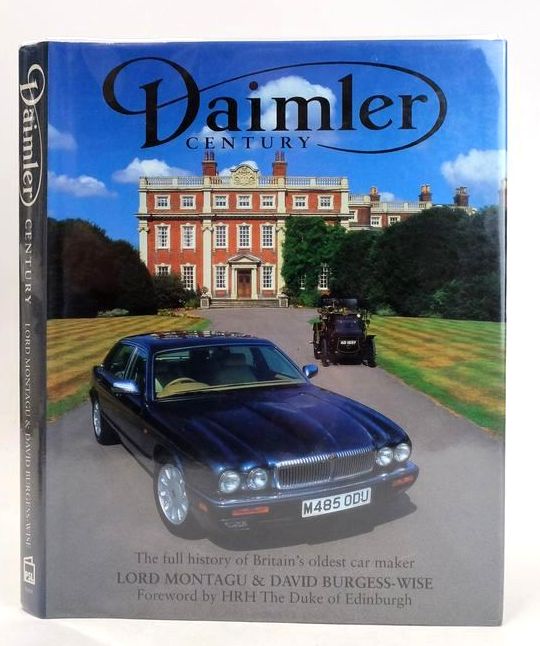

In 1898 they produced the first car body and were among one of the first coachbuilders to build them. The car was commissioned for a Mr Walter Carlisle, the local MP, and was built on a Daimler chassis and an article appeared in the local paper.

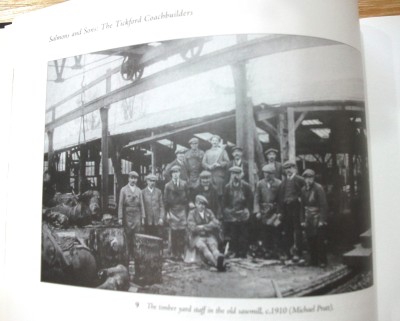

The majority of their car production relied on timber, and this came from local woods and farmland. The Company had their own men to fell and haul the trunks to the yard in Tickford Street. Open sheds were erected to enable the wood to season which could take up to four years. The sawmill was an open structure with an overhead gantry which carried a crane to haul the trunks into position for sawing.

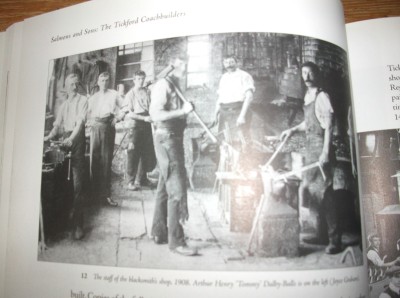

For small or larger runs, the aim of the designers was to produce a body that would suit both the chassis manufacturer and the customer. Once the design was approved a full-size drawing was produced and from this a mock-up body called a pattern was built. Copies were pinned to mobile drawing boards as the sawmill, body shop and mounting shop needed to see them. This practice continued until the Second World War. Salmons also had their own blacksmiths which produced the ironwork fittings which ran until 1955.

Within the big body shop, bodies were mounted onto the chassis and then panelled. The process was basic - chassis came into one end of the shop, bodies mounted and then pushed through to the other end to be panelled. Body makers worked as a gang of three comprising a craftsman, his mate and an apprentice. Even so each body, although it was built to the same pattern, could vary. The body maker always stamped his name with a metal stamp on the rear quarter of the car body. The panels and wings were made by panel beaters, highly skilled craftsmen who could convert flat metal sheets into any required shape or contour.

In 1909 Joseph Jnr died, so his two sons, George and Lucas took over the business. Their early cars had hoods made from leather which took two people to raise and lower them. In 1912 they designed a spring assisted hood which enabled them to be folded from the inside. The company had a good name, attracting many people to the area, therefore creating new housing. They made bodies for companies such as Austin, Benz, Buick, Cadillac, Daimler, Humber, Mercedes, Napier, Waverley, Wolseley and many more besides.

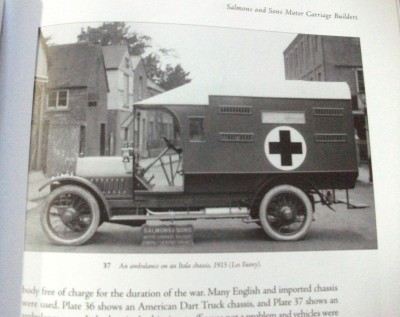

It was during the First World War that many of the apprentices at the works signed up for active service and as part of the war effort Salmons started to build ambulance bodies which were mounted on various chassis.

In the 1920’s the company was still doing well and expanded their offices in London. They were one of the most up to date garages around at the time and had multi storey parking with turntables and lifts and even a golf practice course on the roof!

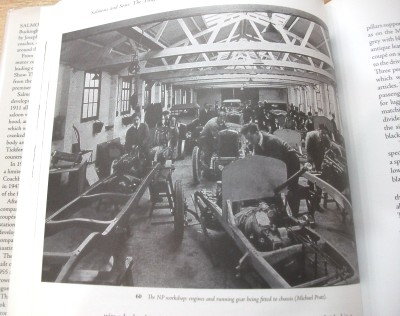

Their highlight was in 1922 where they launched the NP which was the first complete car designed and built at their works. NP stood for Newport Pagnell and the car received good press coverage and said if it proved successful the value of this new venture would be considerable, providing employment for many skilled mechanics. Sadly, sales were disappointing and it went out of production in 1925 - it was literally too expensive to proceed as it couldn’t compete with mass produced cars at a cheaper price.

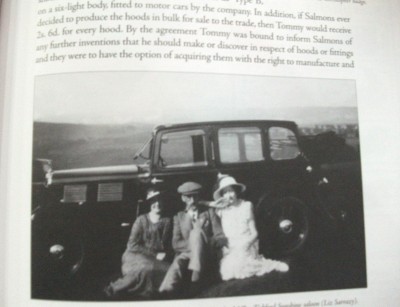

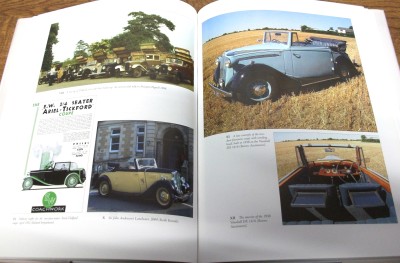

During the 1930’s the company created the Tickford Sunshine saloon which had an easily operated hood mechanism. In order to increase sales and to satisfy customers who wished for a new car but could not afford one, they began to convert standard saloon cars of any make by fitting them with Tickford Winding hoods and this gave them yet another ten years of success.

The Buckinghamshire County Guide contained a short complimentary article on Salmon & Sons whereby it ended that “When you have toured Great Britain in a saloon and seen the roads, do it again in a Tickford and view the scenery”.

After a century as a family business, they became a limited company in 1939 and were now called Salmons and Sons Coachbuilders Limited. Ian Boswell, a wealthy businessman at the time, purchased a controlling interest and became chairman and managing director so everything was looking good until the Second World War broke out.

During the war they went back to making war ambulances and fire tenders as they had done during World War One. The company’s initial government contracts were for ammunition boxes and ladders, and the workshops were modernised to cope with the demand.

George and Lucas Salmons resigned as Directors in 1943 and gave their share to Ian Boswell who became chairman and managing director of a new company registered in February 1943 under the new name of Tickford Ltd which employed 650 staff.

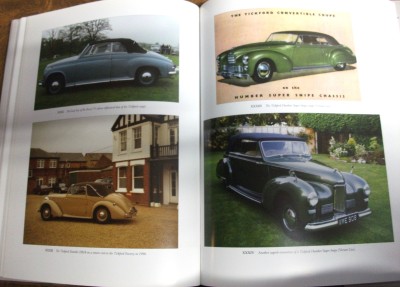

By 1954, Tickford were involved in the production of the DB2/4 for Aston Martin Lagonda and David Brown, owner of Aston Martin bought Tickford Limited. In 1981 Aston Martin created an engineering service subsidiary and chose the name ‘Aston Martin Tickford’. They gained most publicity from adding engineering and tuning to its coachbuilding roots allowing it to develop special products like the MG Maestro Turbo, Sierra Cosworth RS500 plus the 140mph turbocharged Tickford Capri for Ford!

Therefore, after reading this book and doing my own research, I discovered there was indeed a Ford Capri produced by Aston Martin Tickford Ltd in the 1980’s. So, who would have thought that just by wandering round a car show I would have learnt so much about Coachbuilding. The book is a fascinating read and worthy of any book collection especially as, at the time of writing, we have a couple of copies and they are both signed by the author.

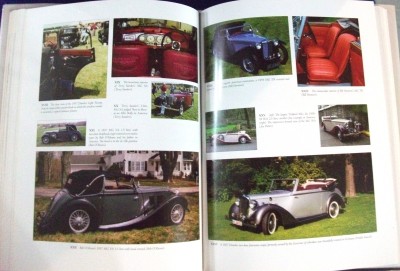

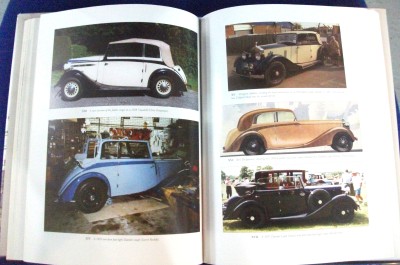

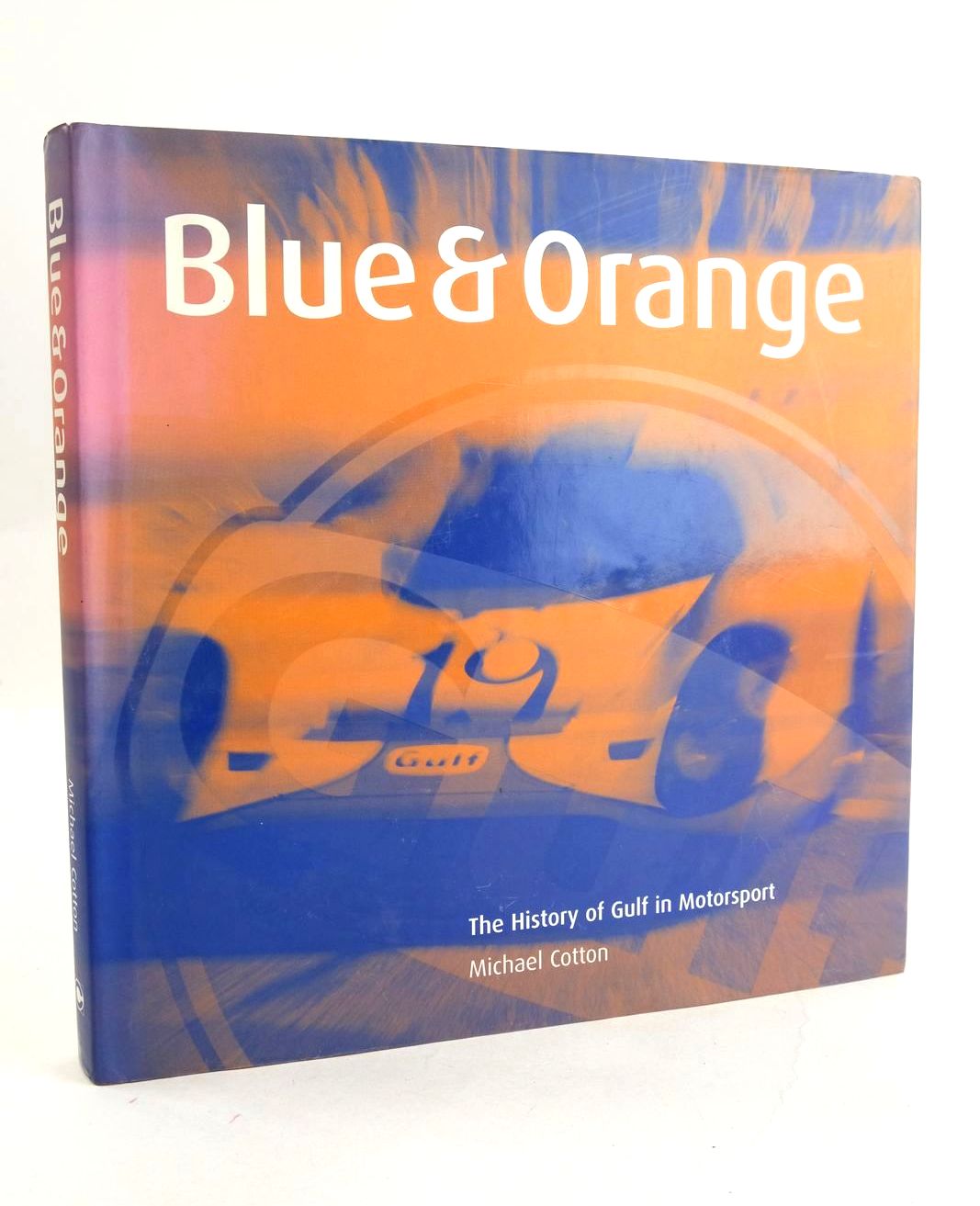

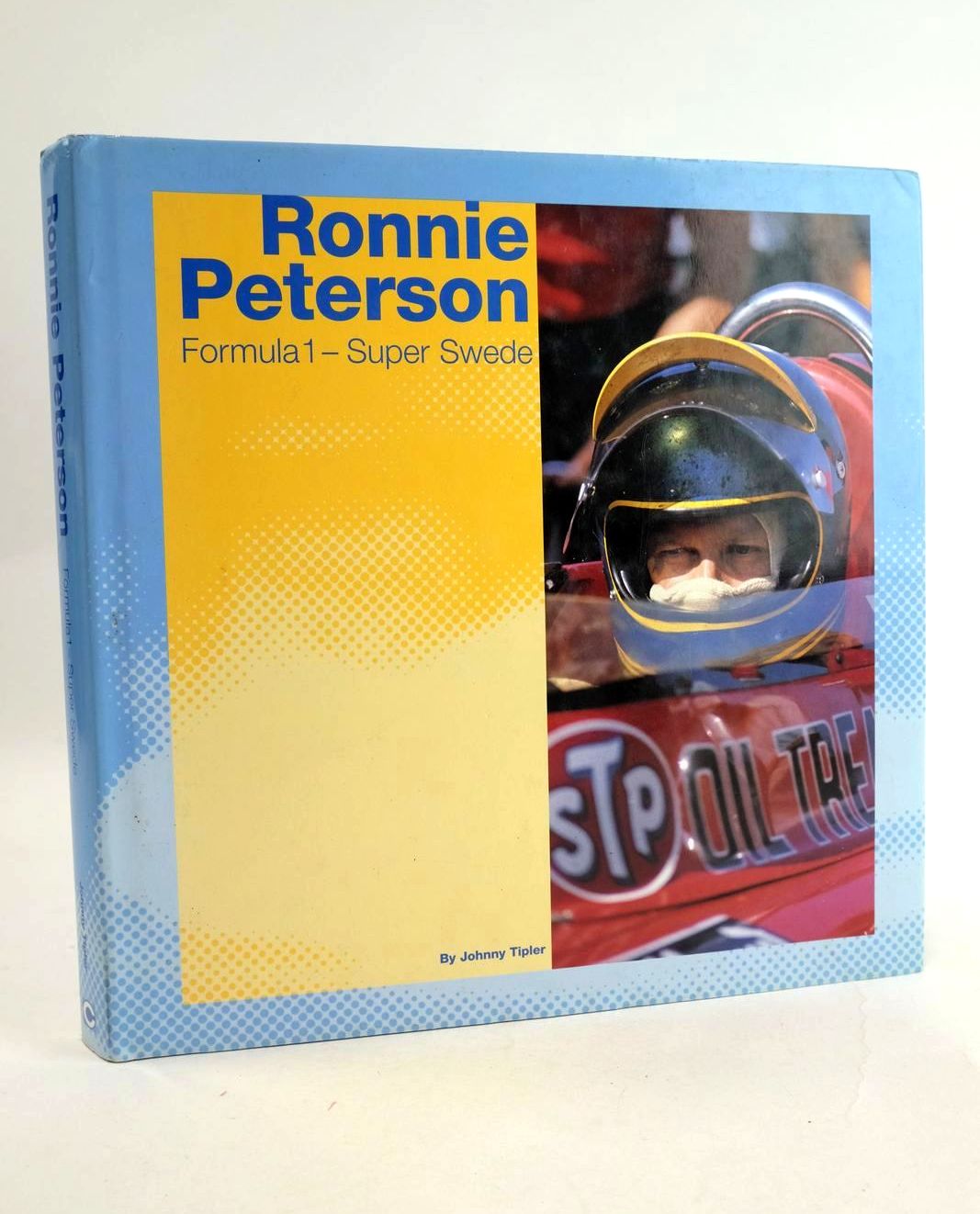

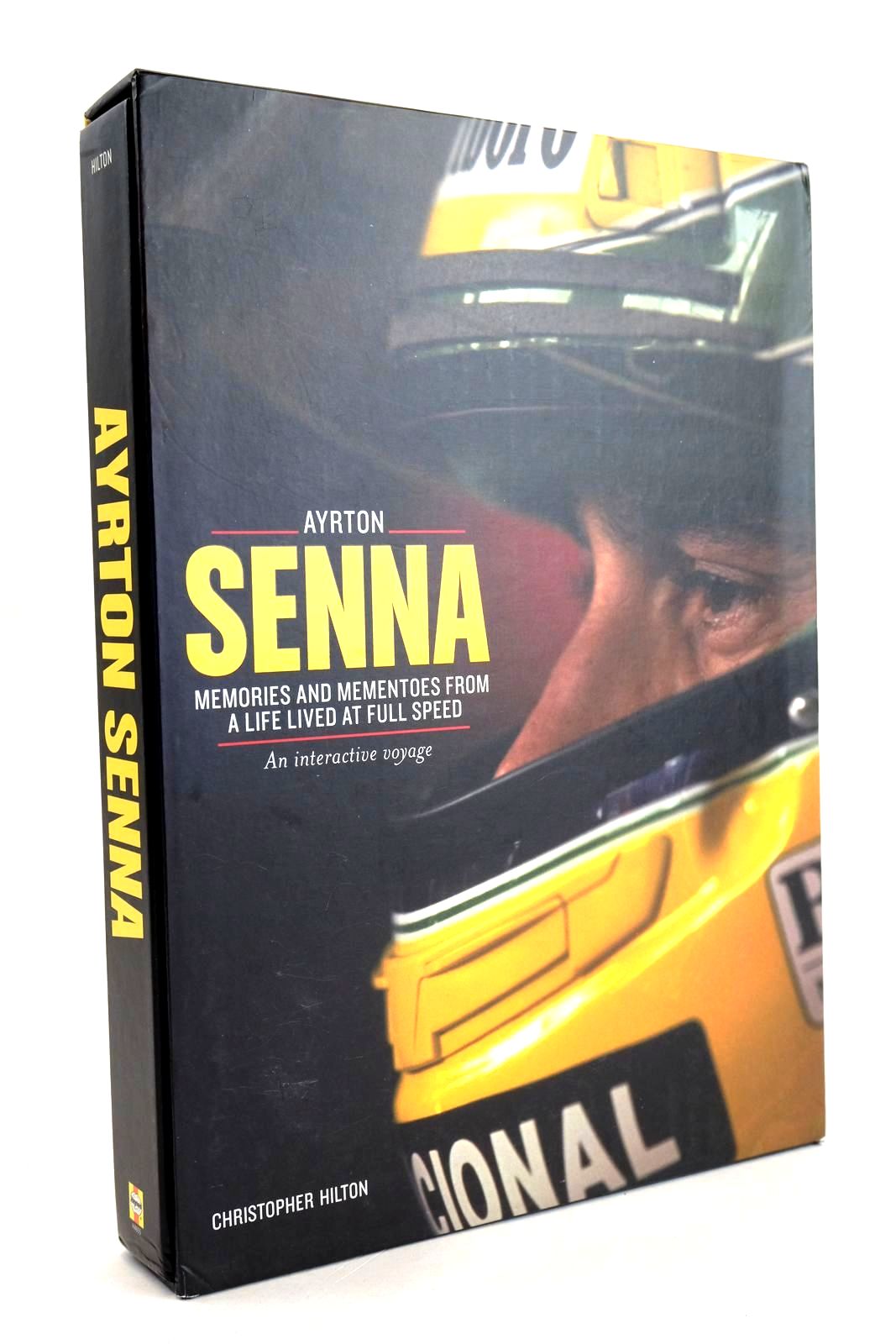

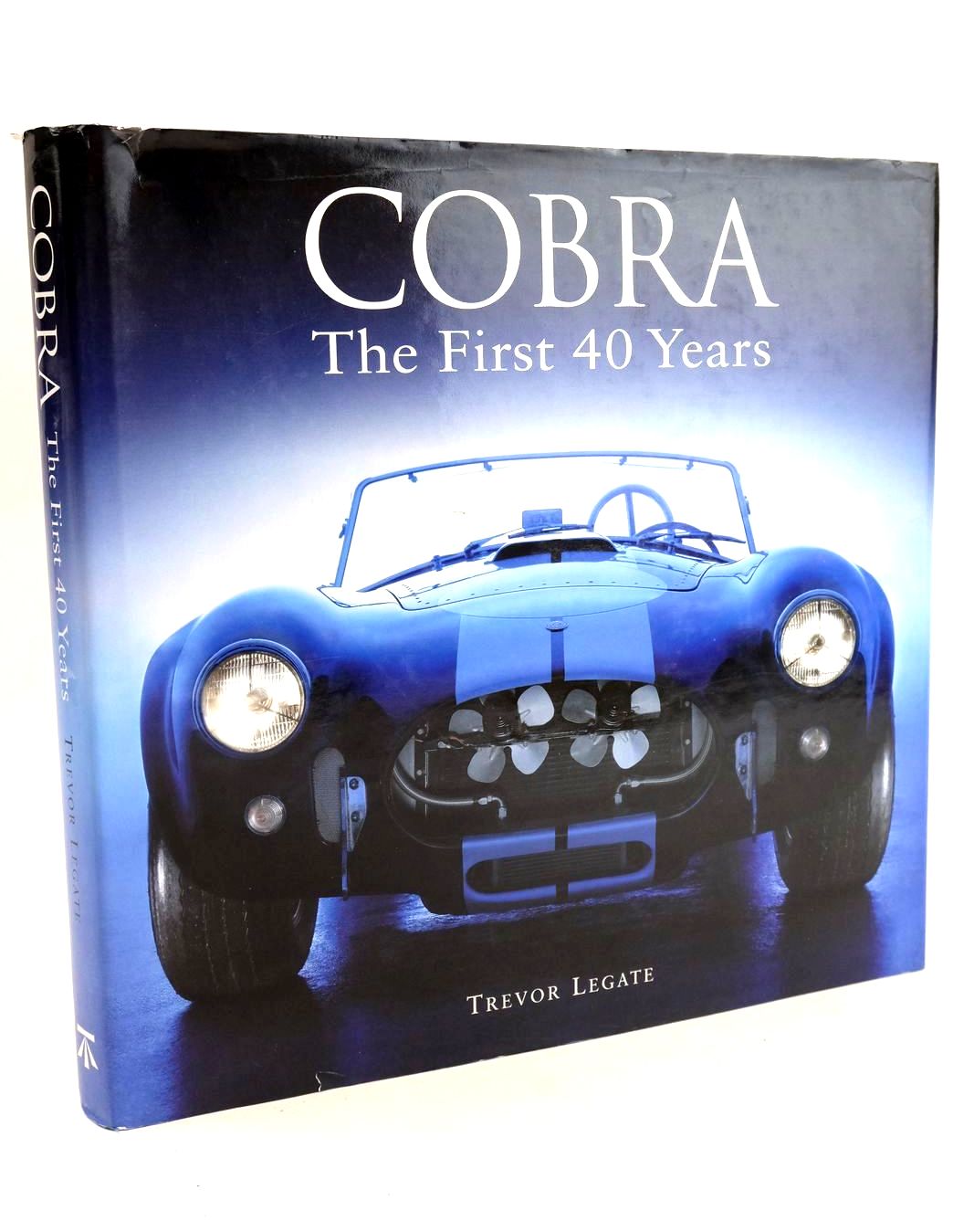

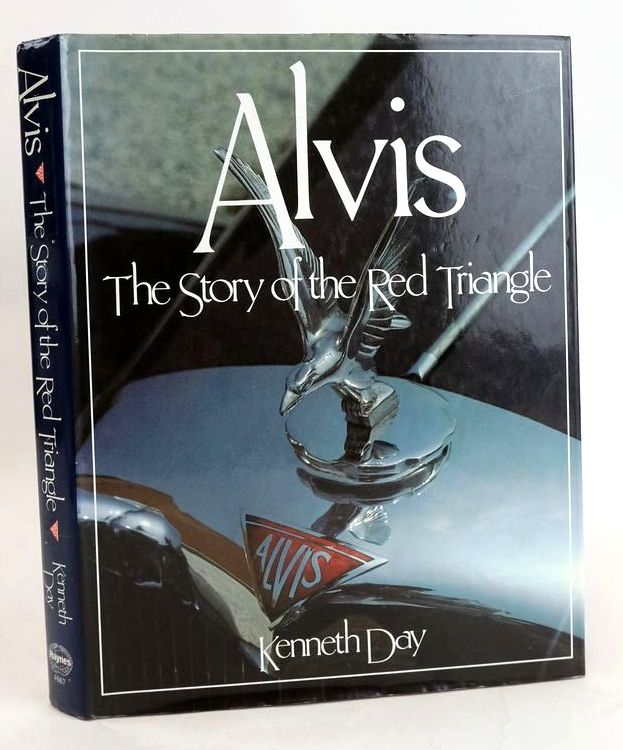

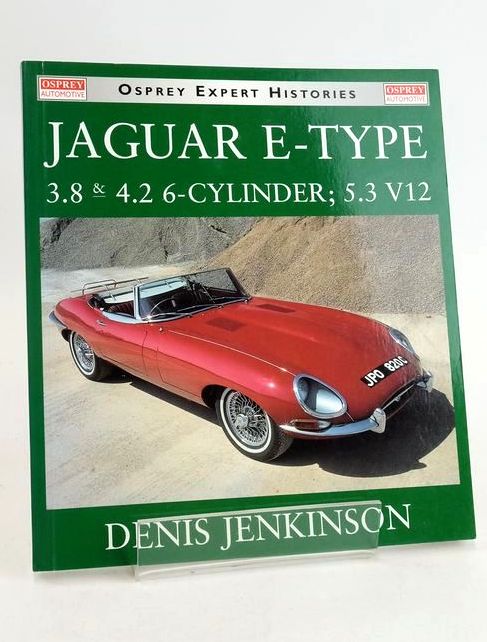

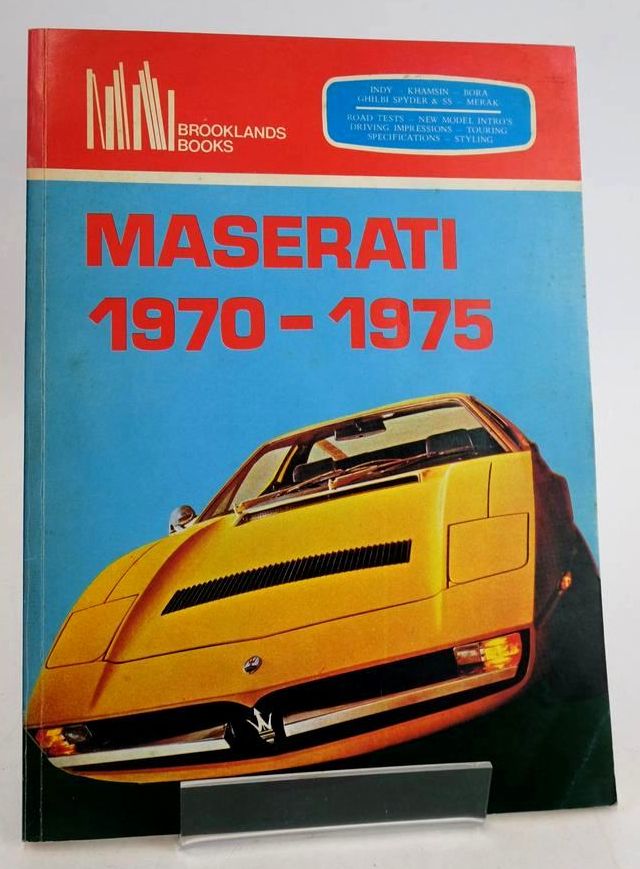

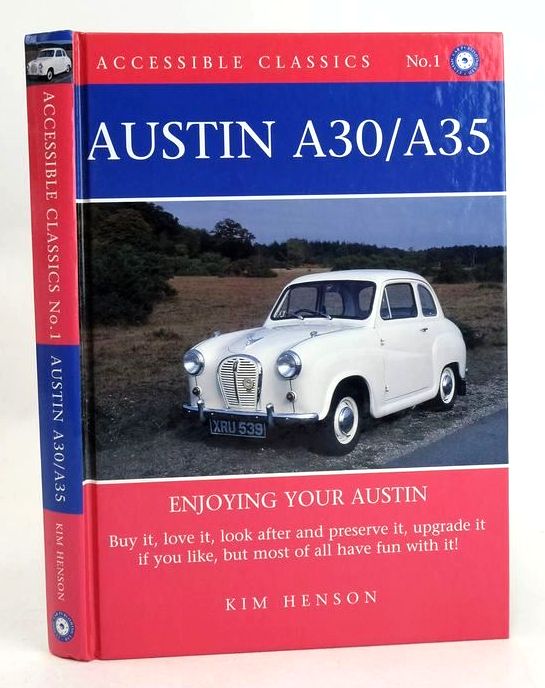

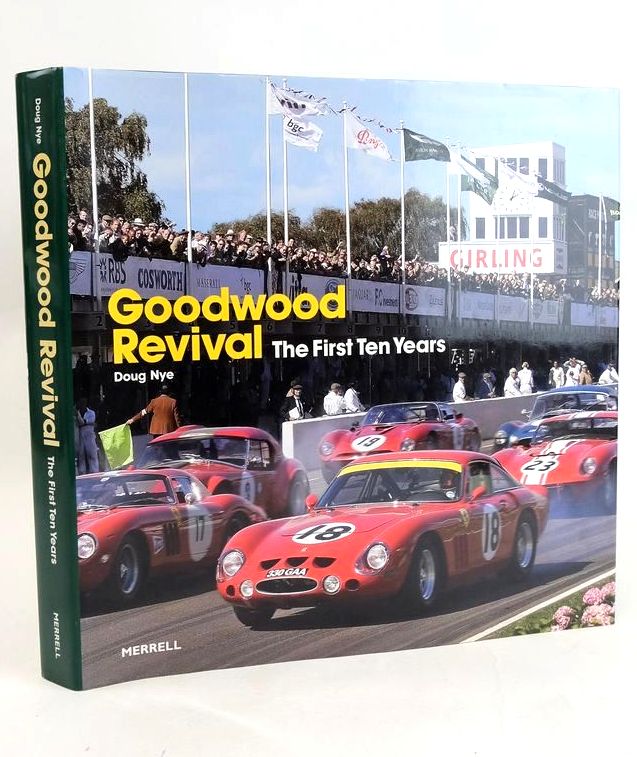

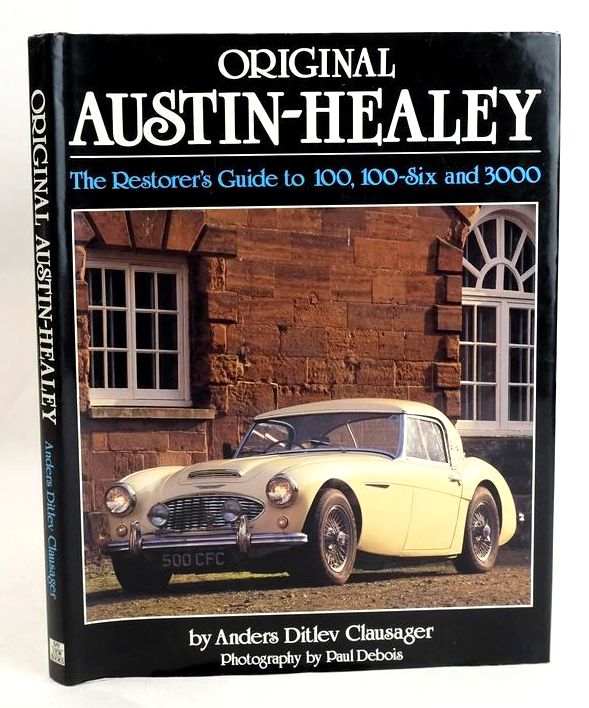

Below is a selection of lovely colour photographs from the book that really show off the cars they built.

Contributed by Lisa

(Published on 1st Nov 2025)