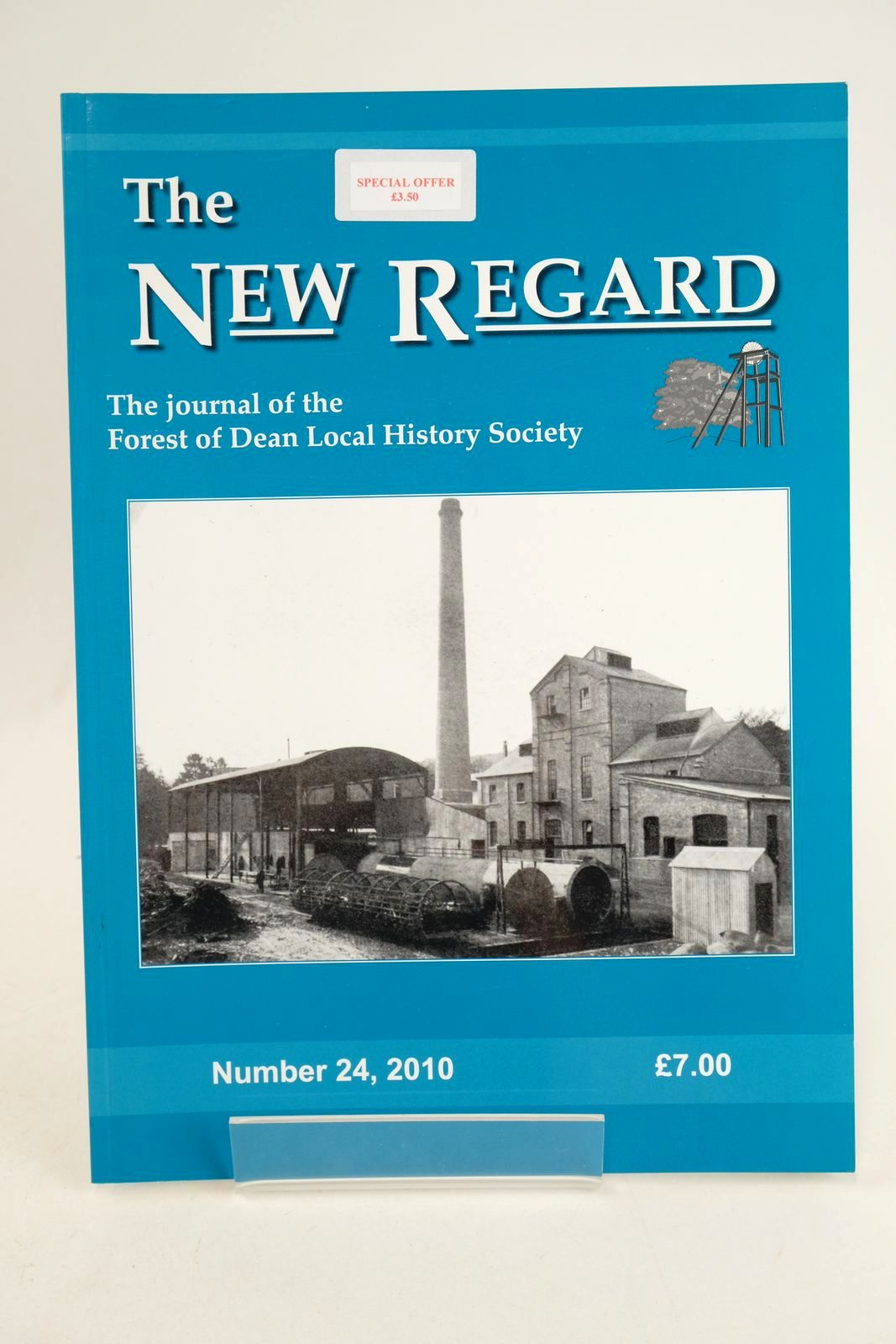

Tintern's Hidden History

Many of us have probably heard of Tintern Abbey - if not, read Sonia's potted history. However, Tintern has a partly hidden history including being the first place in the world where brass was produced by alloying copper with zinc in 1568. So here is my disjointed article on Tintern industrial history.

So why does Tintern have an industrial history?

It is all to do with Location -

-

The fast flowing Angidy river – suitable for driving water wheels, at one point there were 22 of them.

-

Plentiful woodland to make charcoal to heat the furnaces

-

Easy access to the rest of the country via the River Wye and on into the Bristol Channel

-

Local iron mines

Lime kilns

There are various lime kilns scattered throughout the local countryside. They were normally built into the hillside at locations to capitalise on local resources of limestone and charcoal from surrounding woodland. They were filled through a chargehole at the top of the structure, burning limestone to over 1000 °C. The resulting lime was used to make products such as lime mortar, plaster, lime wash and for agricultural purposes to improve the soil.

Abbey Tintern Furnace

A furnace was working on this site from 1590. Starting with a charcoal blast furnace followed by the coke furnaces of the Industrial Age. A waterwheel was used to power bellows which created the blast into the furnace chamber and increased the heat to burn the charcoal and melt the iron ore.

It is likely that the furnace was rebuilt on a number of occasions. One of these changes was the replacement of the earlier bellows with cylinders to power the blast into the furnace. The Angidy Valley was the first place in Britain to use this method. The furnace ceased production in approximately 1828.

Lower Wireworks

This was the site of a large industrial complex which, for three centuries, produced thousands of tons of wire and employed hundreds of wireworkers. Seven buildings covered this site including two forges, a scouring mill, rolling mill and the wiredrawing mill, which were powered by four waterwheels. The wire made here was the end result of a process which began at Abbey Tintern Furnace, where the iron needed to make the wire was smelted. Some of the finest wire in the country was made here in the 1500s and shipped as far away as Turkey and the Barbary Coast. By the 19th century, when Britain was supplying manufactured goods around the world, Angidy wire was said to have been used in the first transatlantic telegraph cable.

Tintern Wireworks bridge

A branch line from the Wye Valley Railway (see previous article) into Tintern was built at huge expense in 1875 to serve the wireworks; this was only done after a successful protest campaign. The ironic thing was that the wireworks went bankrupt before the line was able to open and therefore left this 1.5 mile branch line with little traffic. Nowadays it provides wonderful access to enable us to take walks to Offa's Dyke path and the Devil's Pulpit, through the ancient woodlands of the Wye Valley.

Abbey Mill

This is the site of the only remaining waterwheel on the Angidy valley. The waterwheel was restored in 2008 and now, again, turns. Abbey mill was originally used to produce rolling pins, candlesticks, skittles and wooded coconut shy ball in the Turnery. Also on site was a saw mill which was in use until the 1970s. Today it is a tourist attraction with arts and crafts and an on site cafe just a 150m from Stella Books.

Sources:

Contributed by Adam

(Published on 30th Jun 2016 )